Included Parts

PCB

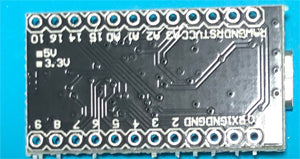

Pro Micro

Tactile Switch and TRRS Jack

Diodes

Acrylic Set

Hardware

Rubber Bump-ons

(RGB Kit) 510 Ohm Resistors

(RGB Kit) YS-SK6812MINI-E Leds

(RGB Kit) 0.1uF Capacitors

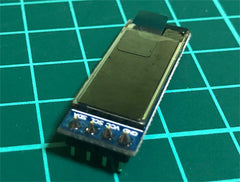

(RGB Kit) SSD1306 OLEDs

Please check the parts list before you begin.

| Name | Quantity | Notes |

|---|---|---|

| PCB | 2 | |

| Pro Micro | 2 | |

| Tactile Switch | 2 | |

| TRRS Jack | 2 | |

| Acrylic | 1 Set (6 pieces) | |

| M2 Spacer 7mm | 20 | |

| M2 Screws 6mm | 40 | |

| Rubber Bump-ons | 8 | |

| Diodes | 80 | 74 needed |

(Slice RGB) RGB Kit

| Name | Quantity | Notes |

|---|---|---|

| 510 Ohm | 2 | |

| 0.1uF Capacitors | 40 | |

| YS-SK6812MINI-E | 71 | |

| OLED | 2 |

Items Needed

| Name | Quantity | Notes |

|---|---|---|

| MX Compatible Keyswitches | 68-71 | 74 total keys |

| MX Keycaps | 68-71 | |

| TRRS Cable | 1 | 3.5mm Aux Cable |

| Stabilizers | 2-6 | GMK Screw-in or C3 recommended. Durock and Zeal stabilizer housings may be too big. |

Necessary Tools

| Name | Notes |

|---|---|

| Soldering Iron | Temperature-Controllable not necessary |

| Thin Solder | ~0.8mm diameter recommended |

| Tweezers | For SMD part assembly |

| Masking Tape | Optional |

| No-Clean Flux | Optional |

Building the Slice

🗹 (Optional) Pro Micro BMP Reinforcement with Epoxy Resin (as of 2/5/2021 Most pro micros sent are already reinforced)

- It takes some time to dry so let's do it first. Also, please read the instructions for drying time of the epoxy.

- Spread resin around the jack but make sure it does not enter.

- Make sure not to flow any into the usb jack of the pro micro.

🗹 Pro Micro Firmware

Pro Micros come pre-flashed with VIA Firmware.

Please refer to the following guide for flashing firmware.

🗹 Separate left and right sides

If not separated for shipping the boards will need to be separated.

- Fold the pcb's in on themselves to separate.

- Use a diagonal pliers or cutters to cut the excess.

- Sand down the pcb if needed.

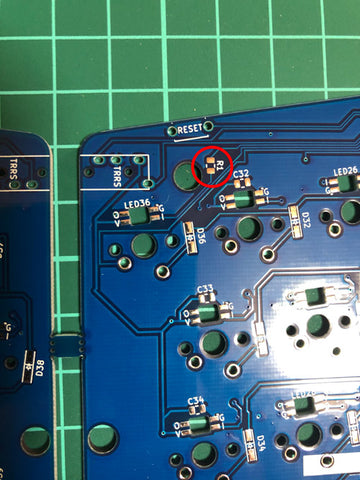

🗹 Install diodes.

- It may be hard to see but if you look close the diode will have a direction.

- Line on the diode must go in the direction of the arrow as shown.

- If the diode is difficult to see look at it in a bright light or use a magnifying glass.

- If the diode is in the wrong direction the key will not work.

- Pre-solder one diode pad.

- With the tweezers in one hand and the iron in the other, place the diode. Melting the solder on the pre-soldered pad.

- Solder the other pad so both pads are soldered.

- Check from the side to see that the diode isn't floating and is flat against the pcb on both sides.

[embed width="320" height="240"]http://www.youtube.com/watch?v=QZMJhrPfYBk&t=0m31s[/embed]

Skip RGB Section

🗹 (RGB) 510 Ohm Resistors

- Install the 510 ohm resistors into R1 and R4 (no specific orientation)

🗹 (RGB) 0.1uF Capacitors

- Above half of the leds are 0.1uF capacitors, which have no specific direction. (See C66 in below image)

- Apply no-clean flux if necessary.

- Apply solder to one pad.

- Install capacitor.

- Apply solder to the other pad.

🗹 (RGB) LEDs

- No-clean flux recommended.

- Drag soldering recommended.

- These LEDs are chained, if one is not installed correctly the others will not work.

- Lower Temperature recommended.

- From the bottom view, align the notch (GND) to G on the pcb.

- Apply no-clean flux.

- Apply a small amount of solder to your iron.

- Drag the iron over one side while holding down the led with your tweezers.

- Drag the iron over the other side.

🗹 Install TRRS and Reset Switches

- Solder one hole of the TRRS jack and to make sure it is flush against the pcb.

- Reheat and push down on the jack to ensure it is flush with the pcb if necessary.

- Push the reset switches into place on the backside of the pcbs.

- Place the TRRS jacks and put masking tape over to prevent movement of the TRRS jack.

- Flip to the front side of the pcb to solder.

🗹 Install pro micros

- No-clean flux recommended.

- Pro Micro build is similar to the Helix or the Corne. See the Helix build guide here.

- Installing the orientation wrong or using too much force could lead to pins ejecting or pin bending.

- Removable pro micro tricks can work here too, you can look them up online incase you ever want to replace your pro micro.

- Solder the spring loaded header to the pro micro, making sure the bottom side faces upward (Non-RGB, long side into the PCB)

- The smaller windows should be on the Pro Micro side. Also, install so both sets of headers have the small windows facing the same orientation.

- Insert the pro micro into the through-hole pads.

- It should lock into place without soldering, but I recommend soldering the other side.

Pro Microハンダ付け pic.twitter.com/2mIe6HFflE

— サリチル酸⌨️自キ温泉ガイド (@Salicylic_acid3) March 21, 2019

Skip RGB Section

🗹 (RGB) OLEDs

- Short the 4 jumpers on both pcbs. We are giving thanks to @foostan and others who helped trailblaze this design.

Tweet - Solder the risers into place. (Masking tape recommended)

- Solder the 4pin header onto the oled.

- Push the oled into the riser.

🗹 (RGB) Test LEDs (See LED Order Below)

- Test your work by plugging the usb into one half or the other half. See also the Corne Cherry Build Guide.

- If you plug in right hand only the last LED may not light up by default even though it's working. Test with both hands connected together.

- LEDs will all glow red if correctly soldered. You may have to go into VIA to turn on a solid color.

- You can toggle the leds on and off by hitting the bottom most left key.

🗹 LED Order and Reflowing LEDs

- If some are not glowing you'll need to reflow the LEDs

- LEDs are chained together in this order so you find the next LED in the chain to reflow.

- If after a few reflow attempts an LED happens to be bad (It happens) you may need to replace it all together. Use of an SMD rework station is recommended.

🗹 Test Board

- Test the board with a tweezers. Make sure all switches are functioning. Use the VIA key tester or another key tester to make sure.

🗹 Switches and Stabilizers

- Peel the top plate paper to reveal the clear acrylic on both sides of each board.

- Install stabilizers to the pcb first. Note Non-RGB Slice: Durock and Zeal stabilizer housings may be too big and not allow the acrylic to sit properly and the switches to sit firm to the pcb. GMK Screw-in are recommended.

- Set the top plate over the stablilizers.

- Insert the switches into the top plate. You may have to solder a few. The 3mm acrylic is big and it's okay if it is touching the pcb at this point.

- Solder the switches into place.

🗹 Acrylic Sandwich

- Screw the four 7mm or 10mm spacers to next to the pro micros for the oled/pro micro display protecting plate.

- Screw the 7mm spacers to the backplate.

- Screw the top plate screws into place to complete the sandwich case.

- Gently push down on the switches to even out the acrylic if necessary.

- Install the display protecting plate.

🗹 Add Bump-ons

- Install bump-ons